China has a “near monopoly” on the extraction of many raw materials critical to the production of semiconductors and other technologies, JPMorgan said Monday, highlighting the importance of key minerals in the escalation of the war trade between the United States and China.

President Biden upped the ante in the ongoing dispute with China last month when he target Chinese products including solar cells, electric vehicles, batteries, steel, aluminum, medical equipment and more, with a series of new tariffs.

“The Biden administration’s latest tariff announcement on $18 billion in Chinese imports has elevated the debate over whether China’s dominance in the critical minerals supply chain will become the latest battleground for strategic competition between the United States and China,” wrote Amy, executive director of strategic research at JPMorgan. Ho, and global head of research Joyce Chang in a note to clients.

In 2022, China produced 68% of the world’s rare earth minerals, which are used for things like magnets and batteries, and 70% of its graphite, which is used in lubricants, electric motors and even nuclear reactors.

However, China’s real dominance lies in its mineral processing capabilities, according to JPMorgan. China has processed 100% of the world’s supply of graphite in 2022, 90% of rare earths and 74% of cobalt (another mineral critical for batteries).

“The growing reliance on critical minerals, which are key inputs for semiconductors, electric vehicles, military weapons, and more, has raised concerns that China could use its dominance in this supply chain to retaliate against U.S. industrial policy,” Ho and Chang warned.

Tit for tat between the United States and China trade war began in 2018, when then-President Donald Trump slapped prices on a range of Chinese goods and raw materials, including solar panels and steel, citing theft of intellectual property (IP) and unfair business practices. Since then, tensions between the world’s two largest superpowers have only intensified, with high stakes battle Intellectual property and semiconductor manufacturing take center stage in the AI boom.

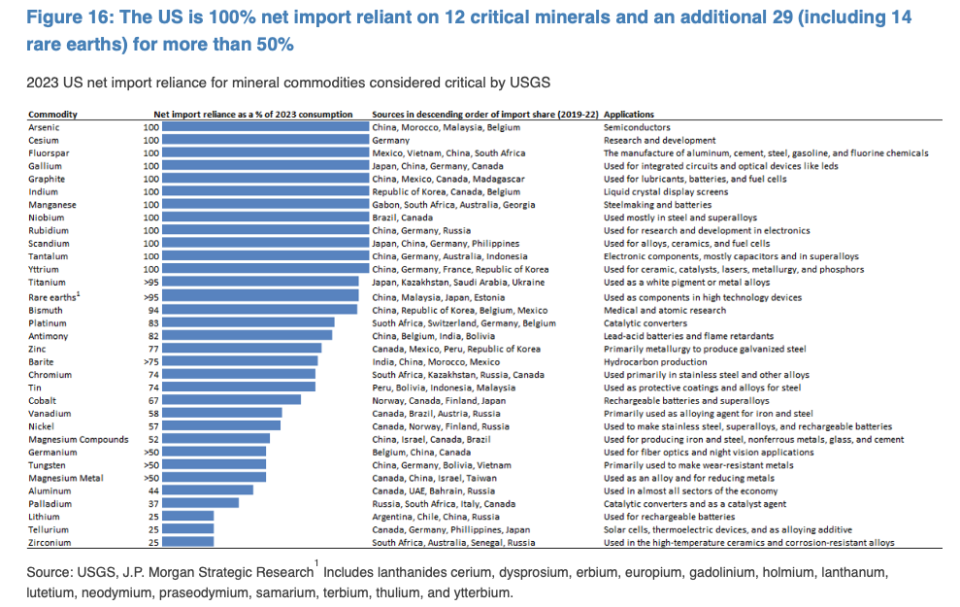

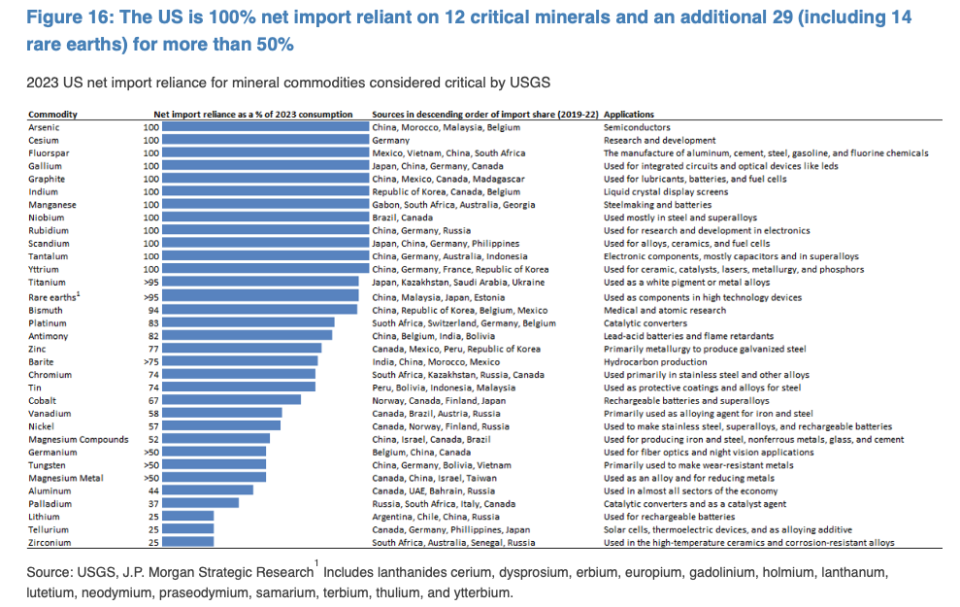

Imported minerals only

Of the minerals that the U.S. Geological Survey identified as critical to the U.S. economy and national security, the United States was 100 percent dependent on imports for 12 of them.

1. Arsenic

Main source: China

Applications: Semiconductors

2. Cesium

Main source: Germany

Applications: Research and development

3. Fluorspar

Main source: Mexico

Applications: Manufacturing of fuel, foams, refrigerants, etc.

4. Gallium

Main source: Japan

Applications: Integrated circuits and optical devices

5. Graphite

Main source: China

Applications: Lubricants, batteries and fuel cells

6. Indium

Main source: South Korea

Applications: Liquid Crystal Display Screens

7. Manganese

Main source: Gabon

Applications: Steel and battery manufacturing

8. Niobium

Main source: Brazil

Applications: Superalloy manufacturing

9. Rubidium

Main source: China

Applications: Electronics research and development

10. Scandium

Main source: Japan

Applications: Manufacturing of alloys, ceramics and fuel cells

11. Tantalum

Main source: China

Applications: Manufacturing of electronic components, capacitors and superalloys

12. Yttrium

Main source: China

Applications: Manufacturing of ceramics and lasers

China is the primary source of five of these 12 essential minerals, and the second or third source for three others: fluorspar, galium and scandium. But China is not the only country the United States relies on for its key minerals. Other major sources include Mexico, Japan and Korea.

The United States relies on imports for 50% or more of its supply of 29 additional minerals beyond the dozen listed above. This includes a net dependence of over 90% on imports of titanium, 14 rare earths and bismuth.

Will China weaponize its “near monopoly” on critical minerals?

With the US-China trade war escalating, minerals could prove an exploitable weak point for Beijing. In a worst-case scenario, where China increases export restrictions on key minerals or implements a total ban, the electronics, oil refining, defense and electric vehicle sectors would be particularly at risk, noted JPMorgan’s Ho and Chang.

Yet, for now, JPMorgan strategists do not foresee a serious mining turf war taking place. “There are growing concerns that China is militarizing its position, but we expect China’s response to remain proportionate and limited based on its past actions,” they wrote Monday, adding that states United States may also turn to alternative suppliers and substitutes.

The two men offered some recommendations for how the United States can stabilize its supply of critical minerals to protect the defense industry, support the transition to electric vehicles and prevent the economic fallout from a possible US trade war. raw materials.

First, Ho and Chang emphasized that creating new mining capacity in the United States is not an option to address America’s dependence on mineral imports. New mining operations take years to get off the ground, carry environmental risks, and regulatory approval in the United States is often uncertain. It takes an average of 16.5 years for a mining project to move from discovery to production in the United States, according to the International Energy Agency. And getting a mine permit alone takes on average seven to 10 years.

Instead of new mining operations, Ho and Chang recommended diversification of mineral supply, implementation of new mining technologies, and strategic storage of key minerals. They estimated that technological innovation and recycling could reduce demand by 20 to 40 percent, while material substitution could ease supply strains and reduce costs over the coming decades. Additionally, strategic stockpiling by the U.S. government and businesses could serve as a buffer against sudden supply chain disruptions.

“There are more opportunities to diversify suppliers of critical minerals than for oil, and countries that are expanding their mining and processing capabilities include allies such as Canada, Australia, the EU and Japan,” they added. “The United States should remain optimistic. »

This story was originally featured on Fortune.com